Dry Claw Vacuum Pumps vs. Oil-Lubricated Pumps: A Guide to Maximise Productivity in the Food Industry

In the fast-paced and competitive sector of food manufacturing, producers are under pressure to increase efficiency, maintain hygiene, and ensure uninterrupted reliability. From thermoforming and vacuum packaging to marinating and product extraction, vacuum systems play a central role in maintaining product quality and process stability.

Selecting the right industrial vacuum pump and technology partner is a strategic decision that affects production reliability and total operating costs.

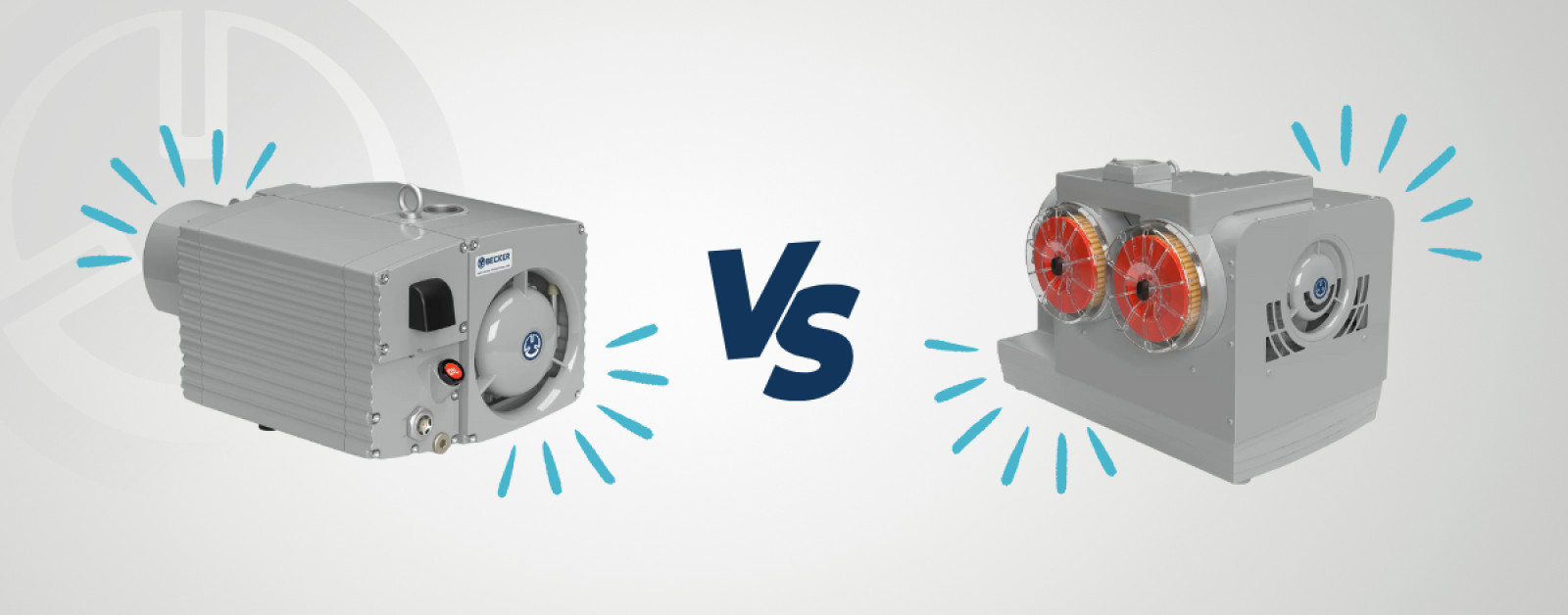

In this article, we explore how Becker’s full range of vacuum technologies, from oil-lubricated rotary vane pumps to oil-free claw pumps, supports every stage of food processing. Each technology offers distinct advantages: oil-lubricated systems deliver precise and stable fine vacuum, while claw pumps provide dry, contactless compression for hygienic, low-maintenance operation.

Explore BECKER's role in Food Packaging and Processing

AN INTRODUCTION TO CLAW VACUUM PUMPS - THE IMPORTANCE OF DEPENDABLE VACUUM TECHNOLOGY IN FOOD PROCESSING:

Vacuum technology is essential to achieving consistency, hygiene, and safety in food packaging and processing applications. Becker’s extended range of claw vacuum pumps uses a non-contact, oil-less compression principle, meaning no oil, graphite, or other lubricants enter the compression chamber. This ensures 100% hygienic operation, ideal for industries with strict food safety regulations such as meat and proteins, poultry, dairy, and confectionery.

Common food industry applications include:

- Thermoforming machines: Deliver consistent vacuum for precise and uniform packaging.

- Spinal cord extraction: Maintain controlled vacuum for accurate meat processing.

- Maple syrup extraction: Ensure product purity through oil-less operation.

- Marinating tumblers: Achieve consistent flavour infusion through stable vacuum performance.

The oil-free operation of Becker claw pumps eliminates the risk of contamination while providing reliable vacuum levels, even under fluctuating loads. Their durable design withstands washdowns, disinfection, and thermal stress, making them ideal for modern food production lines.

SELECTING THE RIGHT CLAW VACUUM PUMP IN FOOD PRODUCTION:

Choosing the correct vacuum pump model for each process stage optimises performance, hygiene, and efficiency – safeguarding product quality and maintaining longer cycle times.

| Model | Ideal Applications | Key Benefits |

|

BCV 100 - 300 |

Thermoforming machines & Vacuum packaging systems. | Flat design options, compact footprint, stable vacuum for continuous operation. |

| BCV 150 | Beef production, Spinal cord extraction. | Precision vacuum control, easy maintenance. |

| BCV 300 | Maple syrup extraction, meat tumblers. | Constant vacuum pressure, smooth process flow. |

The BC PRO variants include additional corrosion protection, ensuring resistance to aggressive cleaning agents and frequent start-stop cycles typical in food production lines. Becker’s VARIAIR frequency inverter technology (VSD) further enhances energy efficiency, achieving up to 30% energy savings while maintaining consistent suction levels.

Explore BECKER's Claw Pump Range

DRY CLAW AND OIL-LUBRICATED VACUUM PUMPS: A COMPLETE APPROACH

In food processing, both oil-lubricated and dry vacuum technologies have critical roles to play. Each offers distinct advantages depending on the application requirements, hygiene standards, and desired vacuum range.

OIL-LUBRICATED VACUUM PUMPS: PRECISION AND DEEP VACUUM

Oil-lubricated rotary vane pumps remain the preferred choice for applications requiring fine or high vacuum levels, where consistent performance and deeper vacuum pressures are essential. They provide:

- Stable, high ultimate vacuum for precision packaging, sealing, and controlled atmosphere processes.

- Smooth, quiet operation ideal for continuous-duty cycles.

- Proven reliability in processes where oil separation and maintenance routines are easily managed.

In food processing environments, oil-lubricated pumps are commonly used in primary packaging, vacuum sealing machines, freeze-drying systems, and fine packaging processes, where a controlled vacuum depth is crucial to maintaining product integrity.

DRY CLAW VACUUM PUMPS: HYGIENE AND LOW MAINTENANCE

As touched upon earlier in our article, dry, contactless claw vacuum pumps operate entirely oil-free, making them ideal for rough vacuum applications and processes where hygiene and low maintenance are priorities. They deliver:

- Clean, oil-free compression, eliminating the risk of contamination in sensitive food environments.

- Low maintenance operation, with no oil changes or exhaust filters to replace.

- Energy-efficient performance, especially when combined with VARIAIR inverter control or integrated into a centralised vacuum system.

These pumps are widely used in thermoforming, marinating, meat processing, and vacuum conveying applications, where dependable rough vacuum levels and consistent suction are essential for product quality and operational efficiency.

Becker’s PRO-series (PRO & PRO-Clean) claw pumps offer enhanced corrosion protection, ensuring resistance to aggressive detergents, high-pressure washdowns, and frequent start-stop cycles typical in food production environments. This guarantees long-term reliability and consistent vacuum performance even in demanding hygiene conditions.

BECKER PUMPS: THE COMPLETE VACUUM SOLUTION FOR FOOD MANUFACTURERS

As a full-line vacuum technology partner, Becker supplies both oil-lubricated and dry claw vacuum pumps, enabling customers to achieve the right balance of performance, hygiene, and efficiency for every stage of production and application. Whether your process demands fine vacuum for precise packaging or rough vacuum for high-throughput forming and processing, Becker’s engineered solutions ensure reliable operation, reduced downtime, and optimal energy efficiency across the entire food manufacturing workflow.

AFTER-SALES SUPPORT AND SERVICE EXCELLENCE FOR FOOD MANUFACTURERS:

Choosing the right vacuum pump technology is only part of the process. Becker provides expert consultation and service support, working closely with food manufacturers to ensure every industrial vacuum pump runs at its optimal operating point with maximum reliability and efficiency.

Our trusted support services include:

- Expert selection advice for your food processing application.

- Rapid access to Original Becker spare parts.

- Rental pumps to maintain uptime during maintenance.

- Flexible service packages that extend pump life and protect the lifetime of your investment.

Learn more about BECKER service and our preventative maintenance vacuum solutions

BECKER - YOUR TRUSTED FULL-LINE VACUUM PARTNER IN THE FOOD SECTOR:

In food processing, there is no universal solution; the right vacuum technology depends on the process, hygiene requirements, and desired vacuum level. Becker’s strength lies in providing both oil-lubricated and dry, contactless claw vacuum technologies, ensuring manufacturers can achieve optimal performance and reliability in every application.

Whether the priority is product purity, energy efficiency, or process stability, Becker delivers engineered vacuum systems backed by trusted local expertise, global support, and over a century of innovation.

Looking for specific data sheets or more information on our consultative approach in food manufacturing, production and packaging?