18,000 Litres of water saved daily : Reusing and minimising wastewater through newly installed water treatment plant.

Powdertech has recently invested in an on-site water treatment plant to improve their water treatment processes. The newly installed water treatment plant allows to save and reuse circa 18,000 litres of water per day, a significant reduction in their daily water consumption.

The plant also ensures that all discharged water is free of contaminants like aluminium, titanium, zinc, magnesium, and more, which helps in reducing environmental impact and contributes positively to the local water network.

Powdertech has designed this water treatment system to extract the chemicals, metals, and other contaminants from their pre-treatment rinse tanks (generated as part of our TiZr and Passivation processes), by filtering the liquid and recirculating it for reuse.

Investing in the water treatment plant shows Powdertech's proactive steps to reduce contaminants, conserve water, and minimise waste.

Water treatment plant set up at Powdertech Surface Science

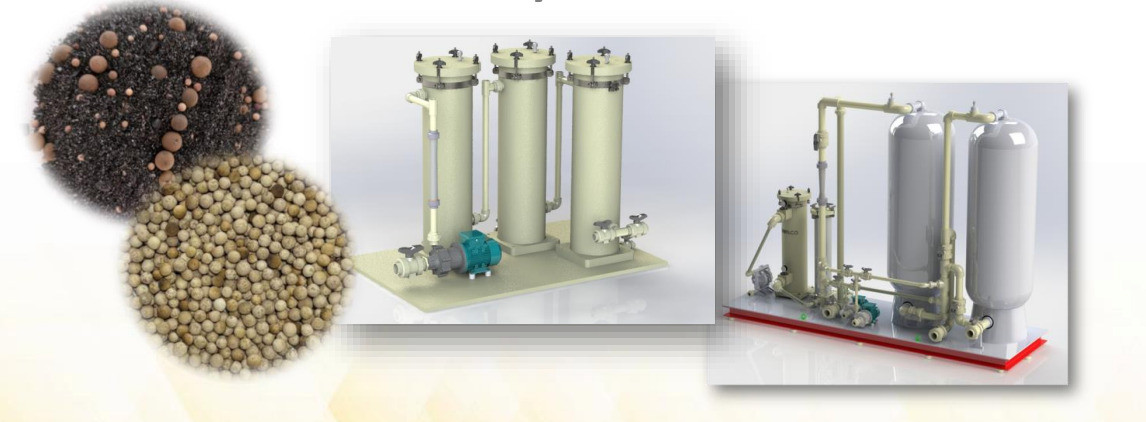

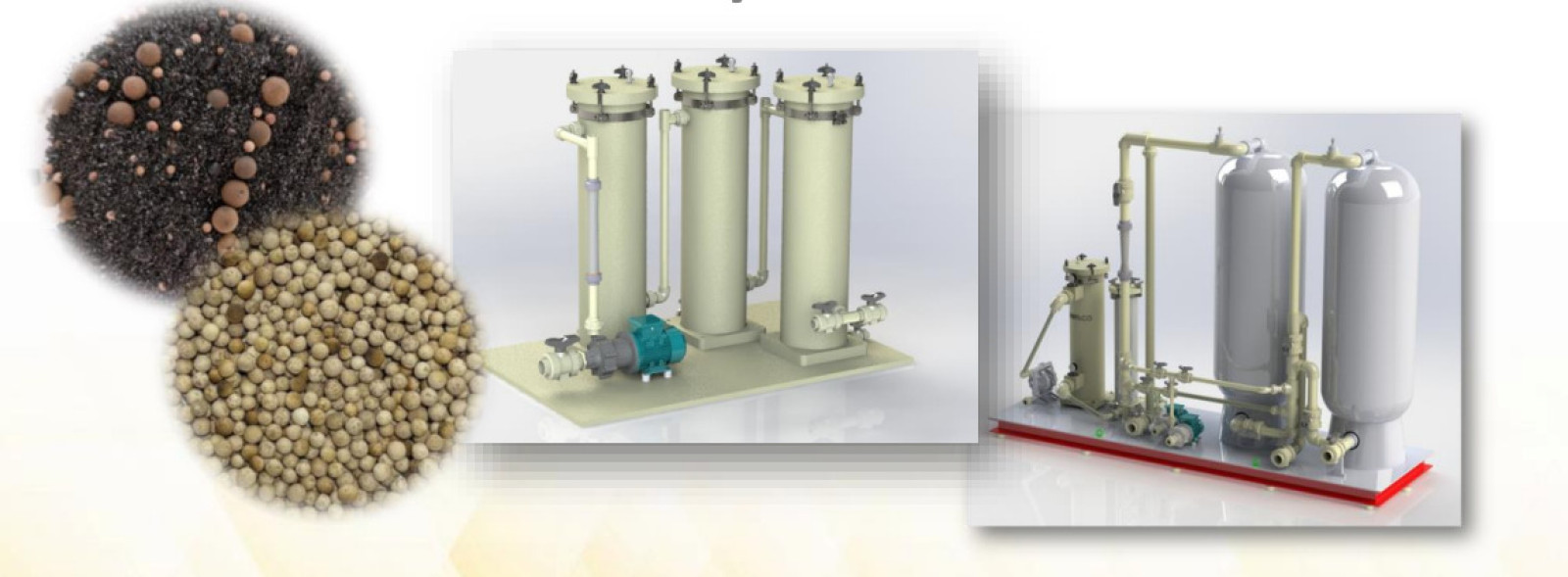

Water treatment plant structure.

The water treatment plant comprises a 5,000-6,000-litre holding tank, activated charcoal process tanks, and four filter media stations for filtration, which ensure that contaminants such as zinc, magnesium, and aluminium are safely filtered out.

The system also integrates an innovative regeneration process for the filter media, allowing them to reuse materials and reduce the need for frequent replacements. This sustainable approach extends the life of the resources and minimises waste, while ensuring the quality of our water discharge.

The process uses two chemicals – hydrochloric (acidic) and caustic (alkaline). This ionises the water, balances the pH levels to neutralise it before it is returned to the tanks for reuse. Contaminants are captured within the four stages of filter media, which will be periodically emptied and then regenerated.

They repurposed their old Keronite process line and saved on unnecessary construction, avoiding disruption. This demonstrates Powdertech's long-term commitment to reducing waste and making efficient use by repurposing the resources they already have.

Benefits beyond Powdertech

Metals, such as magnesium, nickel, copper, iron, titanium, chromium, zinc, and more, when discharged in controlled levels, can easily be treated by wastewater management authorities like Thames Water.

Secondly, Powdertech's local Wastewater Treatment Works (WTW) features biodigesters, which use microbes to create natural gas by digesting the solids recovered from the sewage stream.

The byproduct of this process is a “cake” that is used within fertiliser. This provides an important revenue stream for Thames Water. By controlling the discharge onto the water streams, microbes in the biodigesters are protected, supporting continuous production of natural gas without any hindrance.

This on-site water treatment plant makes Powdertech more self-reliant by repurposing its wastewater before discharging into the water stream, reducing the dependency on Thames Water to process heavy effluents.

Periodically, the water would be discharged as part of regular plant maintenance, but this discharge will be contaminant-free and 100% safe to enter the local Thames wastewater treatment works.

Polishing of wastewater through filters to enable reuse of valuable water.

Sustainability champions behind the project

The estimated cost of the water treatment project is around 120-130k. Powdertech started the project in 2024, and it is aimed to be completed by the end of July 2025. Powdertech's Operations Director, Phil Tyler, and Manufacturing Engineer, Richard Knight, are the leaders behind the execution of the water treatment plant set up and its regular monitoring.

Key driving factors - The bigger picture.

The major driving factor to set up this process was:

-

To improve the quality of water discharge.

-

Reduce and reuse the amount of water consumed by circa 18,000L per day.

-

Introduce fewer contaminants to the water network.

Steps towards sustainability - One project at a time!

This project is just one example of how Powdertech is continuously leading by example. From being the first company to go chrome-free in the UK since 2000 to being proactive towards sustainable water management solutions.

Powdertech is proud to be part of the British manufacturing industry, a sector that is steadily improving its environmental footprint. With ISO 14001 and ISO 9001 certifications, Powdertech is building a culture of responsibility that will help to make their operations more sustainable, demonstrating responsible manufacturing practices that contribute to British circular systems.

The ‘Great 100’ Made in Midlands awards

Powdertech is thrilled to participate in 'The Great 100’ awards by Made in Midlands for the ‘Sustainability Champions’ category. Show your support by filling out the nominations form. And stay tuned to know more about sustainability projects at Powdertech through their ‘Sustainability Spotlight’ series.

#Great100 #BackingBritain #MemberNews #UKManufacturing

.jpg)